DTF Quick Turnaround revolutionizes fashion production with fast, high-quality printing, cutting lead times for hoodies and apparel, enhancing adaptability to market demands, and ensuring timely order fulfillment for business success.

In today’s fast-paced manufacturing landscape, adhering to strict schedules is paramount. Discover how DTF (Direct To Factory) quick turnaround times revolutionize production, ensuring timely delivery without compromising quality. This article explores the significant impact of DTF on production speed, uncovers streamlined processes that enable swift turnaround, and highlights the numerous benefits of efficient, on-time production—a game-changer for any industry.

- Understanding DTF's Impact on Production Speed

- Streamlined Processes: The Key to Quick Turnaround

- Benefits of Timely Production Delivery

Understanding DTF's Impact on Production Speed

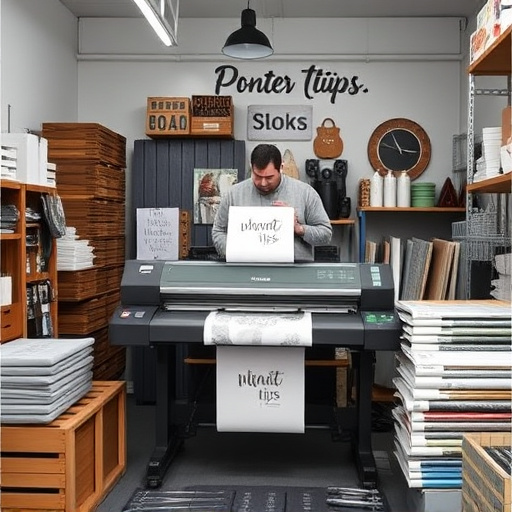

In today’s fast-paced fashion industry, maintaining a strict production schedule is paramount to success. Here, Direct to Fabric (DTF) technology emerges as a game-changer. DTF Quick Turnaround offers an unparalleled advantage by significantly accelerating the manufacturing process without compromising on quality. By eliminating the need for complex printing and cutting steps associated with traditional methods, DTF allows designers and manufacturers to swiftly bring their creative visions to life.

This innovative approach, particularly prominent in DTF printing for hoodies, has streamlined apparel production. With best DTF printers leading the way, brands can now effortlessly meet demand, ensuring that products reach customers faster than ever before. Whether it’s a last-minute design change or a sudden surge in orders, DTF technology is designed to adapt and keep up with the dynamic nature of fashion trends, making it an indispensable asset for any apparel business aiming to stay ahead of the curve.

Streamlined Processes: The Key to Quick Turnaround

In today’s fast-paced market, keeping production schedules on track is paramount for success. This is where DTF (Direct to Fabric) quick turnaround comes into play as a game-changer. By streamlining processes, this innovative technique revolutionizes the way garments are produced, ensuring timely delivery without compromising quality. With DTF printing for light fabrics, the process becomes even more efficient, allowing for bulk DTF shirt production with remarkable speed.

The key to achieving this lies in simplifying every step of the journey from design to delivery. Advanced technologies and precise techniques enable quick drying and printing, eliminating time-consuming manual labor. This streamlined approach not only reduces production lead times but also enhances overall productivity, making it an ideal solution for businesses aiming to stay ahead in the competitive fashion industry.

Benefits of Timely Production Delivery

In today’s fast-paced market, timely production delivery is paramount for any business seeking to stay competitive. DTF (Direct To Fabric) Quick Turnaround plays a pivotal role in achieving this goal. By streamlining the manufacturing process, DTF technology ensures that custom t-shirts and other products can be produced and delivered with remarkable speed, minimizing delays and maximizing efficiency. This agility allows businesses to respond swiftly to changing market demands and customer preferences.

The benefits of such timely production delivery extend far beyond just meeting deadlines. It fosters a culture of responsiveness and flexibility, enabling companies to adapt quickly to new trends and opportunities. Moreover, for businesses relying on custom t-shirts or cold peel DTF transfers as part of their product lines, prompt turnaround times can significantly enhance customer satisfaction and loyalty by guaranteeing that orders are fulfilled without undue wait, ensuring products reach clients when they need them most.

DTF quick turnaround is a game-changer for production scheduling, streamlining processes and delivering timely results. By adopting these efficient practices, manufacturers can significantly reduce lead times, enhance productivity, and stay ahead in today’s competitive market. This focus on speed and accuracy ensures that projects are completed swiftly, meeting the demands of modern production landscapes.